I was able to finish up the drive for the vertical movement. The motor pulls the trolley up via a pulley. Movement up is very slow and I had to PWM the the downward travel to even things out. I definitely need to get a better motor if I manage to get decent scans with this rig.

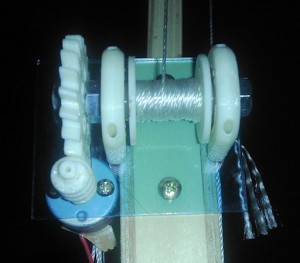

The first worm gear was too rough, I had printed it at .3mm. The new one is printed at .1mm and that makes a big difference in noise and motion. I had to run a pulley at the top to double up the line and roughly halve the load on the motor. Still printing off the end-stop mounts but here’s a shot of where I am on the drive mechanics.